An interceptor management program typically refers to a systematic approach to the maintenance, monitoring, and regulation of interceptor systems. Interceptors are devices used in various industries and infrastructures to capture pollutants or contaminants before they enter the sewer system, or downstream water bodies. They are crucial for preventing environmental contamination and maintaining water quality.

Interceptors are generally required for the following types of establishments:

- Food service establishments where any kind of food is prepared on-site and which result in the production of fats, oils, and grease (FOG)

- Car washes and similar establishments with facilities for servicing vehicles/mechanical equipment

- Linen maintenance establishments including laundromats and other businesses which consists of a central laundry room with at least five (5) washing machines

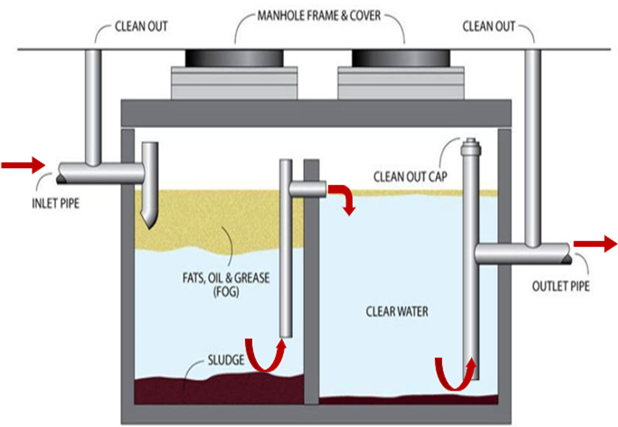

An interceptor is an outside, underground, multi-compartment tank which is installed at a non-domestic facility. They are installed at facilities to prevent non-domestic waste from entering the sewer system and POTW. There are three different types of interceptors:

- Grease Interceptor – The purpose of a grease interceptor is to prevent fats, oils, and grease (FOG) from entering the sewer system and POTW. They are required at all food service establishment where any kind of food is prepared on site which results in the production of FOG

- Oil/Sand Interceptor – The purpose of an oil/sand interceptor is to capture sand and oil before entering the sewer system and POTW. They are required at all car washes and establishments with facilities for servicing vehicles/mechanical equipment

- Lint Interceptor – The purpose of a lint interceptor is to separate lint, strings, buttons, and other debris from the waste stream before entering the sewer system and POTW. They are required at all linen maintenance establishments and other businesses which consist of a central laundry room with at least five (5) washing machines or more

Non-domestic facilities that introduce fats, oils, or grease (FOG), sand and/or lint into the sewage system in quantities or concentrations large enough to potentially cause a blockage, pass-through, or interference to the POTW, are required to install an appropriately sized interceptor(s). Grease Interceptors are required for restaurants, delis, bakeries, sandwich shops, schools, hospitals, assisted and independent living facilities, etc. Oil/Sand Interceptors are required for all car washes and similar establishments which service vehicles/mechanical equipment. Lint Interceptors are required for all laundromats and all establishments with a central laundry room with at least 5 washing machines or more. Domestic facilities are not required to install an interceptor unit.

Interceptors slow down the flow of FOG by baffles and/or a PVC pipe assembly that connects the first and second chamber of the interceptor. As FOG-laden water cools, the FOG separates, congeals, and floats to the top of the interceptor where it is periodically pumped out by a state license septic hauling company by removing the interceptor manhole covers. The “clear” water that remains after the FOG is separated stays in the lower half of the interceptor flows into the second chamber through the baffle wall or the PVC pipe assembly and eventually into the sewer system through the outlet pipe of the second chamber of the interceptor.

The District recommends that all interceptors be pumped out and cleaned every 90 days (i.e., 3 months). Some establishments may find it necessary to clean their interceptors more often, others less often. If an establishment fails an inspection on a regular basis, the owner may need to consider installing a larger interceptor.

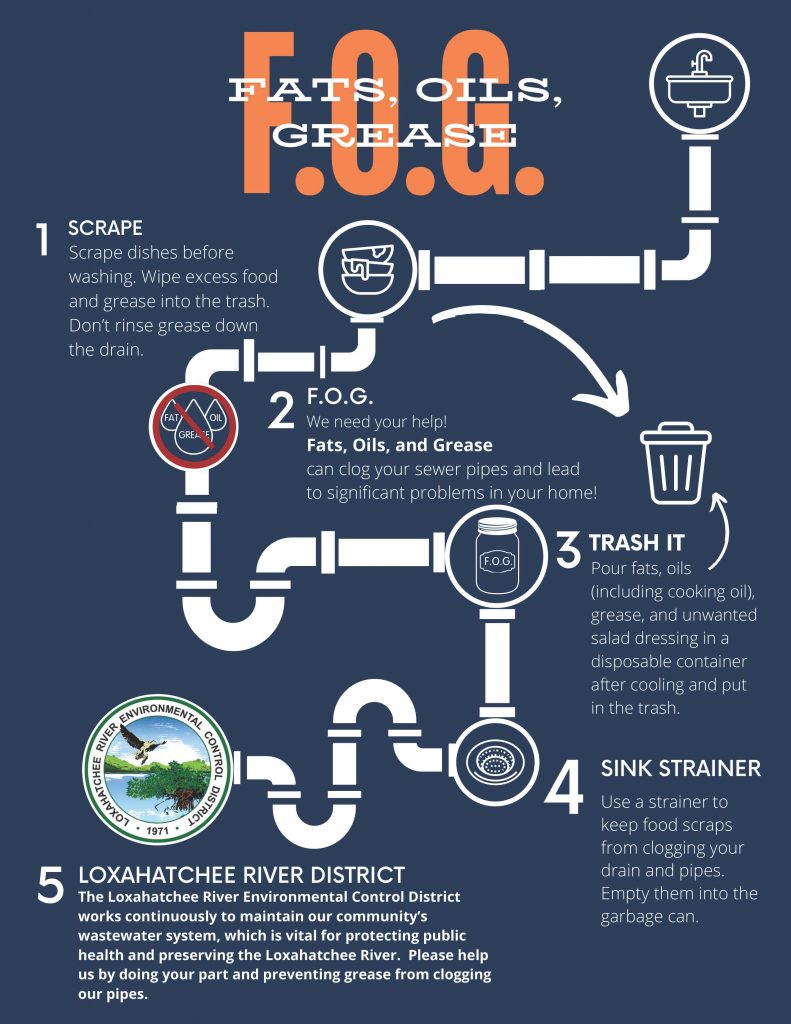

FOG stands for Fats, Oils and Grease, all of which can severely damage and impact the performance of the sanitary sewer system and the publicly owned treatment works (POTW). FOG includes animal (including dairy) and vegetable fats, as well as oils used to cook and prepare food.

Interceptors shall not be shared. Each business location is required to have its own interceptor(s) and its own separate plumbing to the interceptor(s). When the same establishment has multiple discharge points that require installation of interceptors at different locations, such as an institutional facility with a kitchen and a laundry, each use shall be provided with separate plumbing and the required interceptor(s).

If an interceptor fails an inspection, the owner/manager of that establishment will receive a letter in the mail that documents the date the inspection was conducted and what deficiencies were found. The owner/manager has thirty (30) days from the date of the letter to have the deficiencies resolved. Once the deficiencies are resolved, the owner/manager must provide a copy of the invoice, which documents the work completed, and schedule a reinspection with the District’s Industrial Pretreatment Coordinator. Failure to address all deficiencies and to schedule a reinspection will result in further compliance action by the District up to and including submission of a request for enforcement action by the Florida Department of Business and Professional Regulation (DBPR). DBPR will perform a subsequent inspection and can levy fines and/or revoke the business license of the establishment.

For an establishment that is in the process of changing ownership, it is the new owner’s responsibility to notify the District Engineering department of the change of ownership. The new owner(s) are also required to complete and submit an Application for Service and Grease Interceptor Application Questionnaire.